Twin-Screw Plastic Extruder PVC Hot-Cutting Pelletizing Production

line

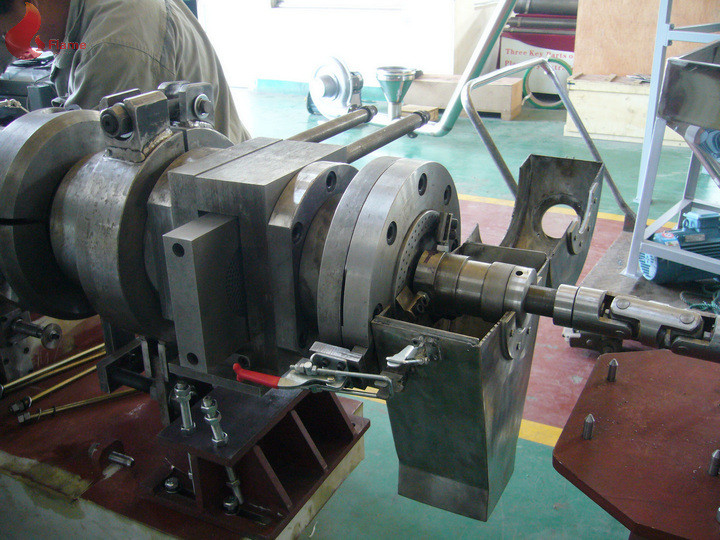

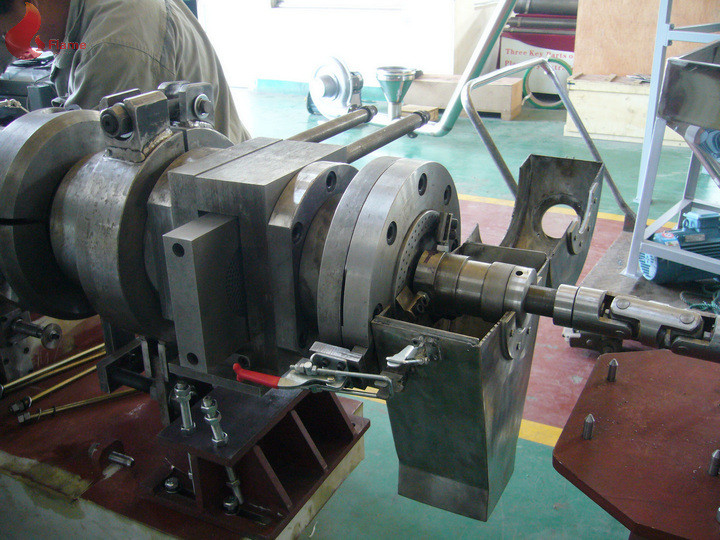

This pelletizing machine is composed by a conical twin-screw

extruder and the correspondingly pelletizing downstream equipment,

it is suitable for the pelletizing of PVC ,PE raw materials with

wood powder or other additives. The pellets produced by this

machine is evenly, solid elegance. The pelletizing downstream

equipment is the die face cutter, air transferring unit, vibration

separating and cooling unit. This pelletizing downstream equipment

has the features of high automation and high production efficiency.

Quick Detail:

The machine produces pellets by hot cutting and mainly is used in

PVC pellets. It is featured as advanced equipment, string

commonality and high capacity.

Description:

Put material in the mixer mixing evenly in the PVC granulation

production line after granulation, this production line mainly

include feeding machine, extruder, die granulation, cutting

machine, vibrating screen, the wind and the aggregate bin, The

final granules satiation equally and can pack directly.

Applications:

Plastic pelletizing

Plastic-wood pelletizing

Specifications:

Model | SJZ55 | SJZ65 | SJZ80 | SJZ92 |

Screw dia.(mm) | 55/110 | 65/132 | 80/156 | 92/188 |

Pellet size(mm) | Ø3-Ø4 | Ø3-Ø4 | Ø3-Ø4 | Ø3-Ø4 |

Power of main motor(Kw) | 22 | 37 | 55 | 110 |

Cutting power(Kw) | 1.1 | 1.1 | 1.1 | 1.5 |

Number of blades | 3 | 3 | 3-4 | 3-6 |

Step number of blowing | 1-2 | 2-3 | 2-3 | 3-4 |

Output(Kg/h) | 100-120 | 220-260 | 320-450 | 650-800 |

Taotal length of production line(mm) | 1200 | 1500 | 1600 | 1850 |

Competitive Advantage:

1. Pelletizing precision is high;

2. Hot-cutting is efficient

3. The productivity is high;

4. Installation and movement is convenien.

Service:

1. Oversea installation guide.

2. Oversea test running

3. Ovsersea worker training

4. Technical support

5. Spare parts supply

6. Technical operation support

7. Formula and processing support

Option

The material will be heating plastified and extrude by extruder.

The granule which be cut out will be cooling by fan and put into

bagsafter sifting

commercial terms

1. Payment: 30% by T/T as advance payment, balance(70%) by T/T

before shipment

2. Lead Time: 60 days after receiving the advance payment

3. Transportation: container, simple package ( PE film, salver)

4.Warranty period: From the day of the use of the machine in the

buyer’s

factory:

(1) The mechanical Parts: 12 months

(2) The electrical Parts: 6 months

5. Installations and Commissioning

(1) Up to date commissioning has been made before shipment

(2) Overseas Commissioning and charges

one or two technicians will be sent to the buyer to guide the

installation and commissioning of the equipment if the customer

requests.

Customers pay the charge of our technicians.

(1) Round-trip Airplane Ticket

(2) Charges of transportation, accommodation and communication

(3) The allowance for the technicians is USD 80 per day for one

person.

(4) An interpreter is needed.

6. Spare parts:

Spare parts for one year are needed for the customers, and we

suggest

that customers should buy the spare parts. (Fittings list will be

provided.)

7. English manual, Figuration drawing, and footing drawings are

provided.