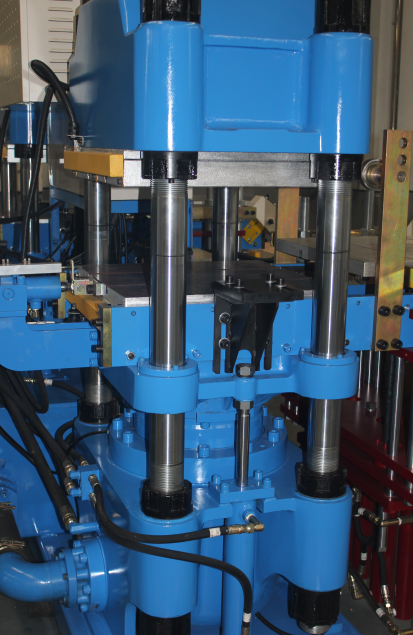

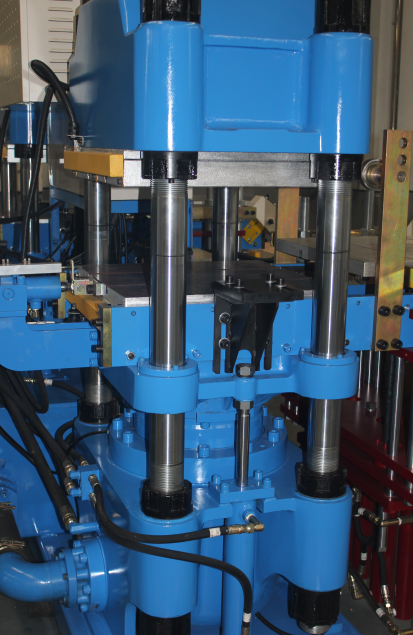

| Type | TWP-200T |

| Clapping force(TON) | 200 |

| Stroke(MM) | 250 |

| Working Plate Size(MM) | 550*560 |

| Dimeter of cyhnder(MM) | 355 |

| Horse powet(HP) | 10*2 |

| Heater power(KW) | 25 |

| Total power(KW) | 42 |

| Gross weight(KG) | 7000 |

| Machine size(MM) | 2900*2200*2000 |

Machine characteristics

4RT mold opening is the machine type with multiple

functions,suitable for the two-laype and three-layer

molds.

Double powers, double oil pumps, double motors and double oil

coolers are applied for the two axles to

work independently.

The oil system is unique in design with good stability, faster

lift-up and lift-down speed compared with

other brands when unloading/loading mold.

With the function of slow speed alignment adjusting, the adjustment

is more precise and safe.

The accurate placement of the loading/unloading mold has the 100%

placement safety design, protecting

the mold from being damaged.

The speed of mold raising and closing can be adjusted accurately

and safely.

Vulcanizing machine daily inspection and maintenance

A. routine inspection and maintenance

1) check whether the photoelectric mold closing device is sensitive

and reliable;

2) check the part of the electric heating board to see whether the

fixing of the electric heating board is firm

and whether the wiring is short circuit;

3) check whether there is oil leakage in motor oil pump, piping and

valve;

4) check the height of fuel tank level;

5) check the flow of cooling water;

6) check for abnormal sounds in motor oil pump, piping, valve,

etc.;

7) the machine up and running, hours after the oil temperature

should be generally within 35 ° C ~ 50 ° C;

8) check whether the system pressure is normal.